Forward AM Gaining Traction at Global Automotive OEMs

AM has made a high-impact entry in the automotive industry. While OEMs have predominantly adopted it for rapid prototyping, there has recently been a strong shift to a focus on end-use parts.

According to the Deloitte report‚ “3D Opportunity in the Automotive Industry”, as a driver of product innovation AM has the potential to become a true game-changer in this industry. Leveraging maximum design freedom as its core benefit, AM makes component design and production possible with far fewer limitations than traditional manufacturing processes. This new flexibility makes mass-customized component production economically feasible. Moreover, AM enable value-adding functionalities to be integrated, such as electrical wiring through hollow structures, lower weight through digitally optimized lattice structures, and previously unfeasible complex geometries. All together, these AM processes enable the creation of faster, safer, lighter, and more efficient vehicles of the future.

Over the last months, we at Forward AM have realized several projects together with leading automotive OEMs that reflect this shift towards a broader application of AM in this industry. By “thinking additive” we enabled groundbreaking new applications and unlocked major benefits for our customers:

- Functional prototyping together with Daimler: Our material Ultrasint® PA6 MF minimized development time and cost by creating and printing an NVH optimized engine mount ready for real-world testing. Read the complete use case here.

- Visual design prototyping for Hymer: When an exact physical representation of the look and feel of the final part is needed, AM is the fastest and most cost-competitive approach. We achieved this for Hymer’s radical VisionVenture concept van by designing and printing the wheel arch, the exterior side panels, and an interior lamp. Discover the use case here.

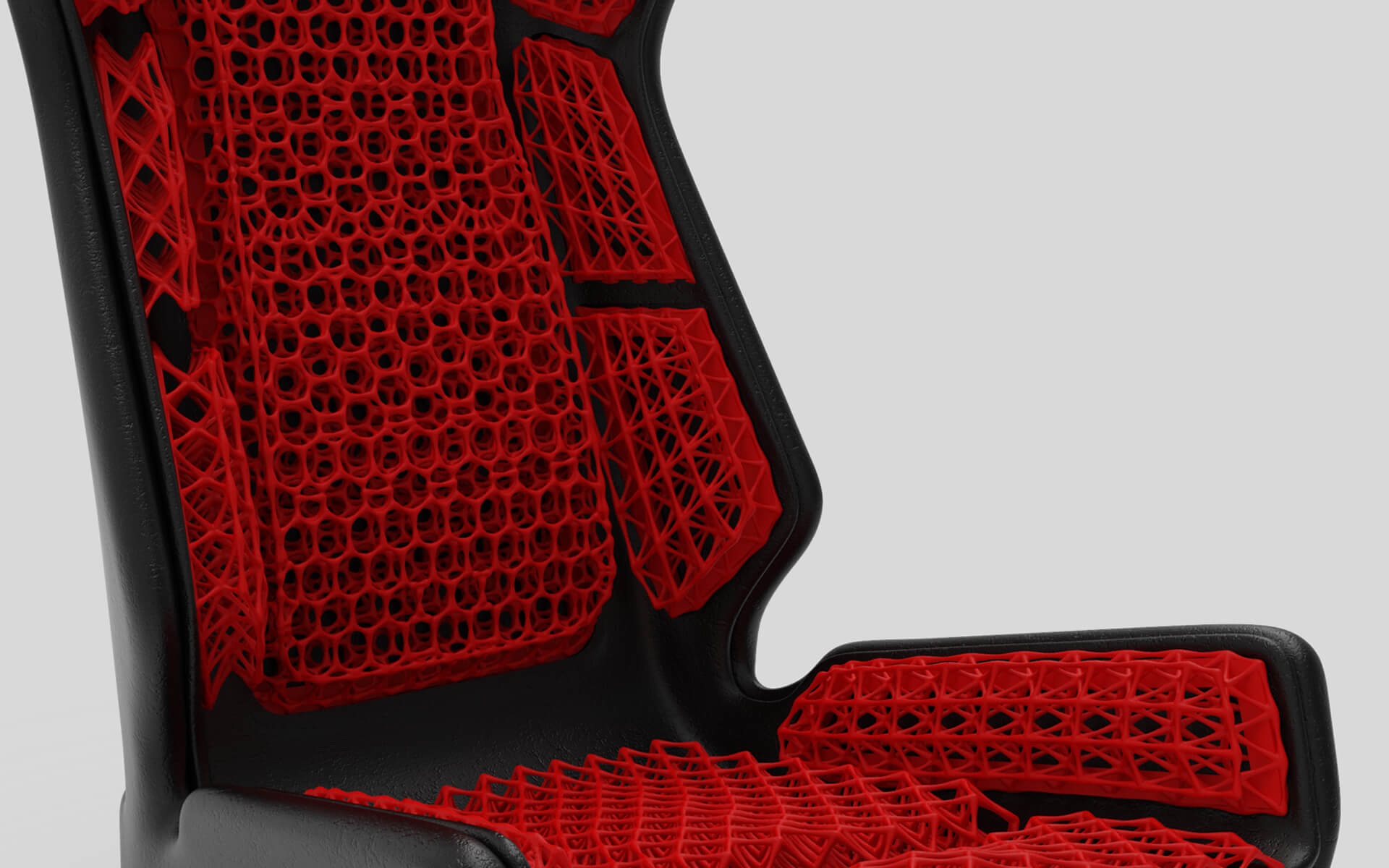

- New designs for Oechsler to meet the latest industry requirements: In a joint project, we developed a 3D printed seat as a prime example of how AM can improve automotive interior parts. Watch our webinar here and enjoy our deep dive into this project.

At Forward AM, we support our automotive customers end-to-end throughout the whole process. We accompany them in their migration to AM – from the very first idea, through digital design optimization and precise performance simulation, to consultancy on the ideal technology and AM material for the final printed part. By close cooperation, we deliver proof of concept and complete ease of mind when making the transition to AM. Helping our customers taking the next step, our support goes well beyond the final printed part: We provide a comprehensive range of post-processing methods to achieve the desired surface finish of the printed part, meeting the very high requirements of leading automotive OEMs.

Curious to find out more about what we can do for your automotive projects? Read our whitepaper on automotive interior applications – and discover how our Ultrasint® TPU01 enables outstanding solutions to meet the global industry’s latest requirements!

Share this page

Other Blog Posts

Forward AM and the UltiMaker Factor 4 – Delivering Industrial-grade Performance

Forward AM offers a wide range of high-performance and certified materials that open a huge range of new 3D printing applications…

LAYERbyLAYER: A Conversation with Jörg Gerken of rpm rapid product manufacturing

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.

LAYERbyLAYER: A Conversation with Janet Dickinson of Endeavor 3D

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.