Discover the Extensive Metal Filament World of Forward AM

Metal 3D printing has various advantages and can be used in different applications. However, the process to receive the final metal object is different from usual 3D printing processes. The part must be printed, the object must be debound, and lastly sintered. Often not all steps can be carried out by one party. Many print the objects themselves, but then face the challenge of not having their own debinding and sintering system, making the process from the idea to the final product rather lengthy and an organizational challenge.

With our new D&S Portal and our metal filaments, as well as our brand-new Ultrafuse® Support Layer, Forward AM wants to lower organizational hurdles and provide a smooth and easier process.

Discover Forward AM`s Ultrafuse® Metal Filaments

Forward AM offers two different Ultrafuse® metal filaments – Ultrafuse® 316L and Ultrafuse® 17-4 PH. Those innovative metal filaments are stainless steel composites. Ultrafuse® Metal Filaments combine greater freedom of design with a lower total cost of ownership – printing metal parts more accessible, faster, and affordable.

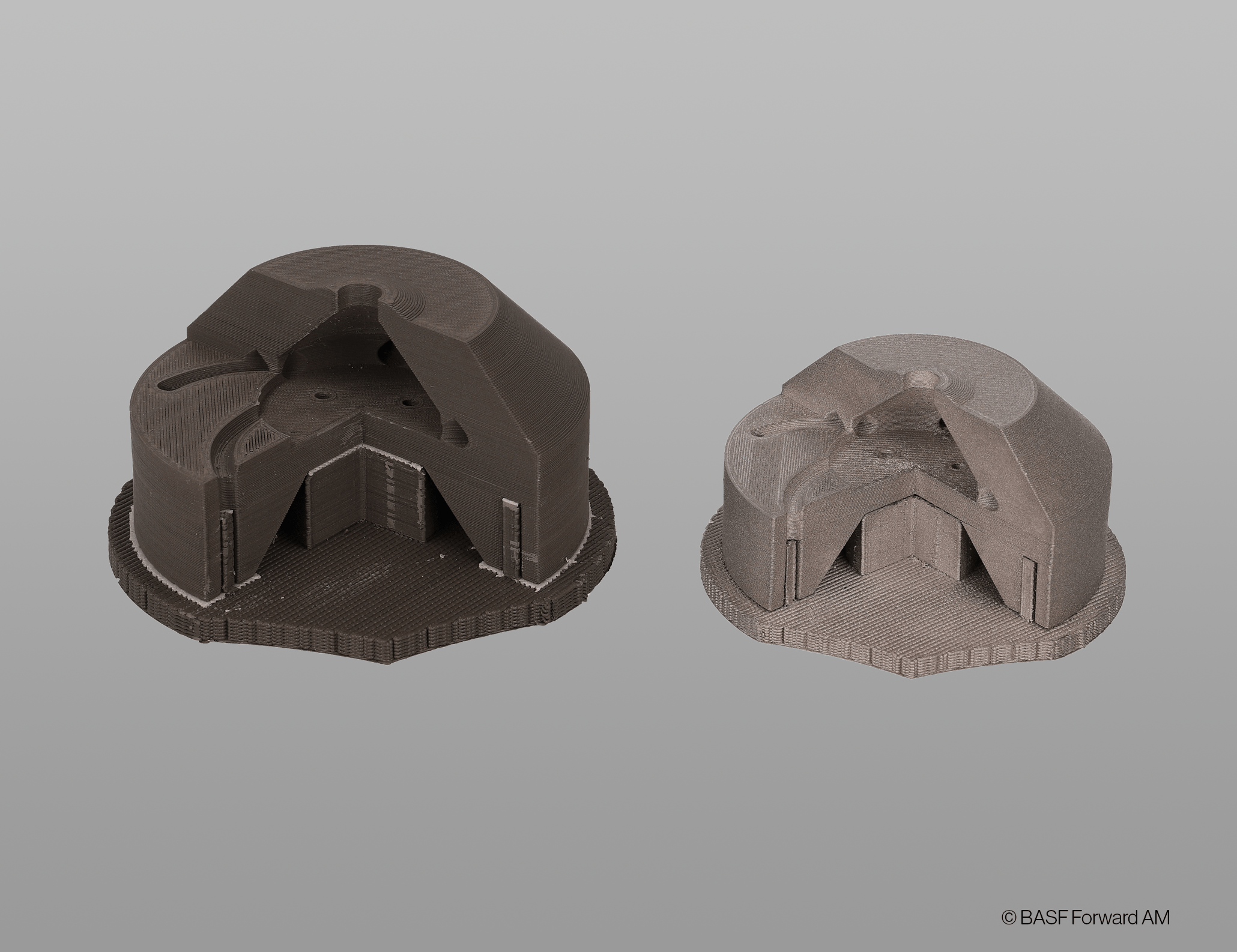

Through the debinding and sintering process, the part printed with Ultrafuse® 316L obtains properties like hardness and strength. This metal filament can be used on all open source FFF printers and allows easy as well as affordable 3D printing. Furthermore, the filament is compatible with both Bowden and direct-drive extruders. It is often used for applications such as tooling, functional prototypes, small series production as well as jigs and fixtures.

As well in the metal filaments portfolio is Ultrafuse® 17-4 PH. It is ideal for petrochemistry, aerospace, automotive, and medical industries as it can be fully heat-treated to high strength and hardness levels. Parts printed with Ultrafuse® 17-4 PH obtain their final properties through a catalytic debinding and sintering process known as traditional Metal Injection Molding. The Ultrafuse® 17-4 PH is affordable and easy to print. Furthermore, it has good corrosion resistance and a wide range of post-processing options for green parts. It is often used for functional prototypes, jigs, fixtures, or tooling.

Ultrafuse® Support Layer more design freedom than ever before

Our new Ultrafuse® Support Layer joined the portfolio on the 24th of May 2022. The goal of Forward AM’s brand-new Ultrafuse® Support Layer* is to prevent parts from sticking or sintering to the support during debinding and sintering. In the past, the metal part would often need a detailed post-processing session to achieve the final product. The solution to that problem lies within the metal injection molding industry. There, setters, jigs, brackets, and support structures are being used to prevent artifacts within the debinding and sintering process. This approach is now brought and transferred to MFFF. It was never easier to produce metal parts without excessive post-processing of the metal parts which increases the overall probability of success dramatically. Plus, it adds a new design freedom to the sintering technology.

Please note that Ultrafuse Support Layer is unsuitable for a standalone printing process. It should be printed as a thin layer attached to the support structures in dual extrusion prints.

Discover our D&S Portal - Debinding and Sintering was never this easy

As explained above, the metal process from the printer to the final product is different from the usual FFF process. If you use 3D printing services like Sculpteo, they will take care of those extra steps. However, if you print the parts yourself, the debinding and sintering process can often not be carried out in-house. This is due to the fact that D&S is an elaborate process, and many don’t have the capacity to carry it out in-house. To make the whole process easier, we launched our Debinding and Sintering order management portal in April of 2022. After you create an account on the site and top-up your D&S balance with vouchers from your distributor, you can book a spot at our service providers, who will do the debinding and sintering job for you. You can track your order during the whole process, and after the finished process, you will receive the finished parts. Within the D&S Portal, you have automatic cost calculation, integrated logistics, and preparation planning, providing complete control of resource usage.

If you want a more detailed explanation, check out our user guidelines.

Metal 3D printing can be an excellent asset for different applications. If you want to know more about this type of 3D printing or 3D printing in general, do not hesitate to check out our website or contact a member of Forward AM directly. We are happy to answer your questions.

* This product is not intended for sale, distribution or use in the US and Canada and is not available to our customers in those countries. While the descriptions, designs, data, and information contained herein are presented in good faith and believed to be accurate, it is provided for inspiration only. Because many factors may affect processing or application/use, we recommend that you perform independent tests to determine the suitability and proper use of a product for your particular purpose. NO WARRANTIES OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE MADE REGARDING PRODUCTS DESCRIBED HEREIN, OR THAT THIS CONTENT MAY BE USED WITHOUT INFRINGING THE INTELLECTUAL PROPERTY OF OTHERS. IN NO CASE SHALL DESCRIPTIONS, INFORMATION, DATA, OR DESIGNS DESCRIBED HEREIN BE CONSIDERED A PART OF OUR TERMS AND CONDITIONS OF SALE.

Share this page

Other Blog Posts

Forward AM and the UltiMaker Factor 4 – Delivering Industrial-grade Performance

Forward AM offers a wide range of high-performance and certified materials that open a huge range of new 3D printing applications…

LAYERbyLAYER: A Conversation with Jörg Gerken of rpm rapid product manufacturing

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.

LAYERbyLAYER: A Conversation with Janet Dickinson of Endeavor 3D

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.