Discover Our New Flexible Filaments!

The Forward AM filaments portfolio offers our customers a comprehensive range of Ultrafuse® materials and perfect-fit filaments for their specific applications and projects.

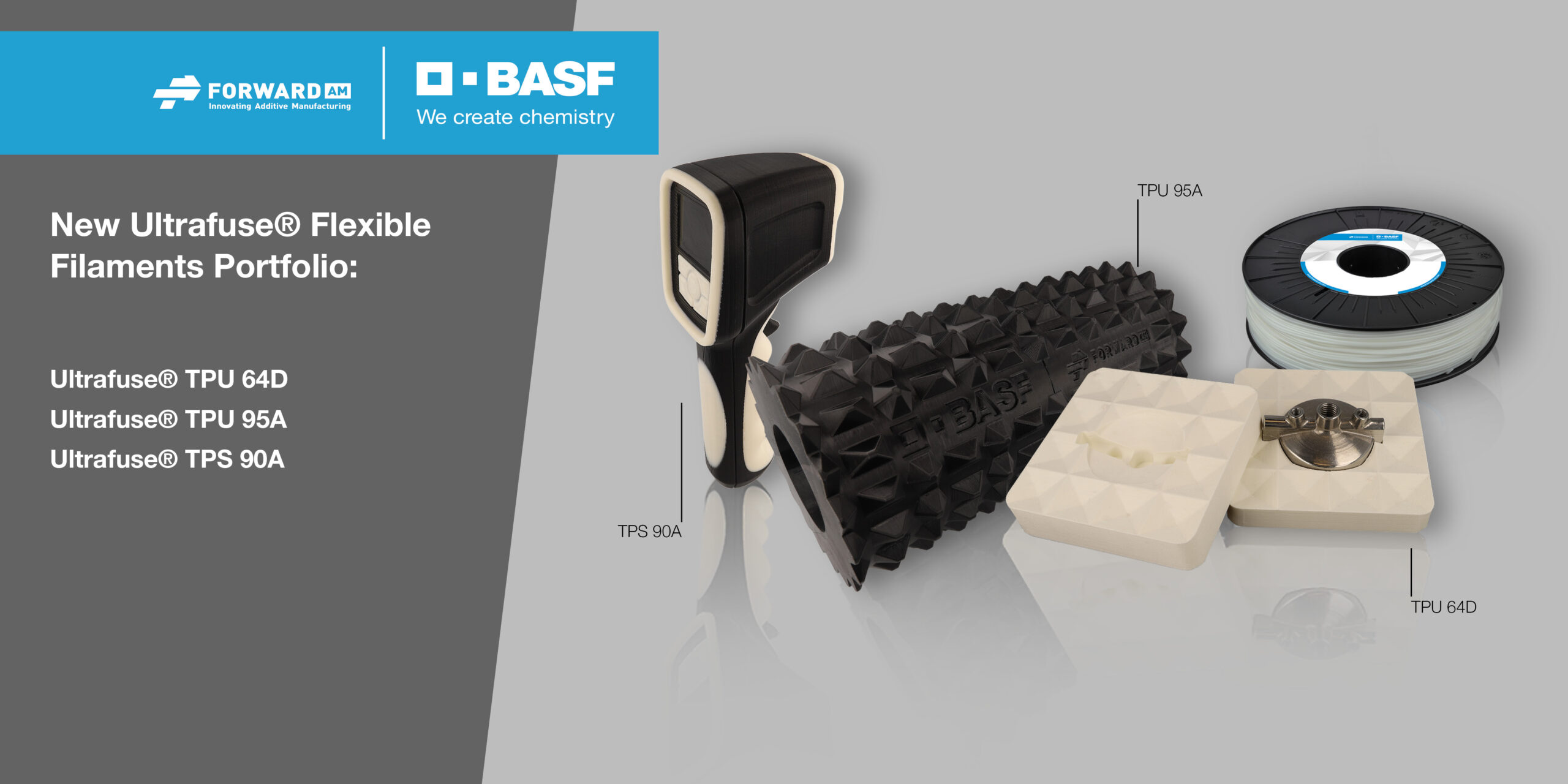

Since the beginning of September our FFF portfolio is even broader, as our flexible filament line now features three new materials:

- Ultrafuse® TPU 95A

- Ultrafuse® TPU 64D

- Ultrafuse® TPS 90A

Our flexible filaments portfolio offers advanced Additive Manufacturing materials specifically tailored to the most demanding industrial applications – especially where long-term component flexibility is required. Adding to the already available filaments Ultrafuse® TPU 85A and Ultrafuse® TPC 45D, our new three materials deliver clear benefits, providing an even wider range for our customers to choose from and optimize their applications.

Let’s take a closer look at the three newcomers!

Ultrafuse® TPU 95A and Ultrafuse® TPU 64D are, just like Ultrafuse® TPU 85A, based on the legacy of Elastollan® – the thermoplastic polyurethane established by BASF. Ultrafuse® TPUs not only represent maximum reliability but also consistent product quality and cost-efficiency. With its great abrasion resistance, Ultrafuse® TPU 95A is ideal for wear-and-tear applications and impresses with good handleability. It’s easy to use and compatible with both direct-drive and Bowden drive 3D printers, making it perfect for fast printing.

Ultrafuse® TPU 64D is based on BASF’s strong legacy in flexible materials. With its high resistance to impact, wear and abrasion, this is an outstandingly strong yet flexible filament for FFF. Its suitability for all FFF printers, compatibility with water-soluble support and its high resistance to oil, greases, oxygen, and ozone means Ultrafuse® TPU 64D is an ideal alternative for parts made from conventional ABS and rubber, and makes it highly suitable for tooling, jigs, and fixtures.

Ultrafuse® TPS 90A was developed especially for Fused Filament Fabrication and offers an outstanding non-slip soft touch. The excellent layer adhesion responsible for the special smooth surface creates an excellent haptic rare in FFF-manufactured components. Combined with its low moisture uptake and very good low-temperature flexibility, this makes Ultrafuse® TPS 90A the perfect choice for appliance handles plus limited-series seals and gaskets.

Are you keen to discover more about our new flexible filaments? Head over to our Forward AM materials website.

If you have any questions concerning our AM materials or 3D printing applications and technologies, feel free to contact us at any time – we’re looking forward to supporting you!

Share this page

Other Blog Posts

Forward AM and the UltiMaker Factor 4 – Delivering Industrial-grade Performance

Forward AM offers a wide range of high-performance and certified materials that open a huge range of new 3D printing applications…

LAYERbyLAYER: A Conversation with Jörg Gerken of rpm rapid product manufacturing

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.

LAYERbyLAYER: A Conversation with Janet Dickinson of Endeavor 3D

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.