Creating chemistry for a sustainable future

Sustainability is the biggest challenge of our time – and BASF has set itself ambitious commitments and pursues numerous initiatives to tackle this challenge.

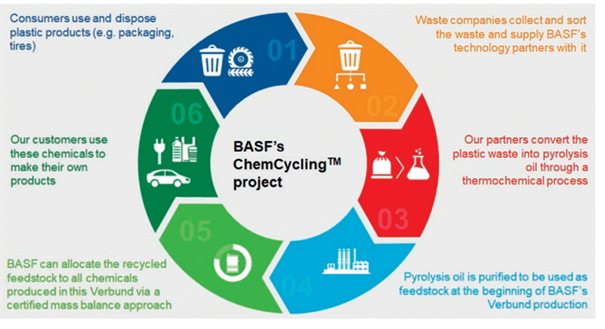

One important pillar of BASF’s contribution to building a more circular economy for plastics is ChemCyclingTM, a chemical recycling project aiming at manufacturing products from chemically recycled plastic waste on an industrial scale.

While plastics do have proven benefits during their use phase – for example preservation of food loss in packaging applications and lightweight construction of vehicles, plastic waste has become a major global challenge. Globally, around 250 million metric tons of plastic waste are generated each year, and around 70% of the plastic waste in Europe is not recycled but incinerated or landfilled. The remaining 30% are mechanically recycled. But in order to reduce plastic waste significantly, it is essential to keep it in the material cycle. ChemCyclingTM makes it possible to recycle plastic waste which cannot be processed by mechanical recycling, like tires, mixed plastic waste, or dirty packaging.

Closing the loop from plastic waste to virgin-grade products

In broad terms, the plastic manufacturing process refers to the series of steps required to turn raw oil and natural gas into plastic products. The process starts with transforming oil and natural gas into hydrocarbon monomers that are then linked together into long chains known as polymer plastics.

In the ChemCyclingTM project, BASF works with partners to further develop the pyrolysis technology which turns plastic waste into a secondary raw material called pyrolysis oil. This is then fed into BASF’s Verbund production at the beginning of the value chain, thereby saving fossil resources. By using a third-party audited mass balance approach, the share of recycled material is allocated to certain products manufactured in the Verbund. These products are independently certified and have the same properties as those manufactured from fossil feedstock. Customers can therefore further process them in the same way as conventionally manufactured products and use them in demanding applications.

Share this page

Other Blog Posts

Forward AM and the UltiMaker Factor 4 – Delivering Industrial-grade Performance

Forward AM offers a wide range of high-performance and certified materials that open a huge range of new 3D printing applications…

LAYERbyLAYER: A Conversation with Jörg Gerken of rpm rapid product manufacturing

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.

LAYERbyLAYER: A Conversation with Janet Dickinson of Endeavor 3D

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.