Share this page

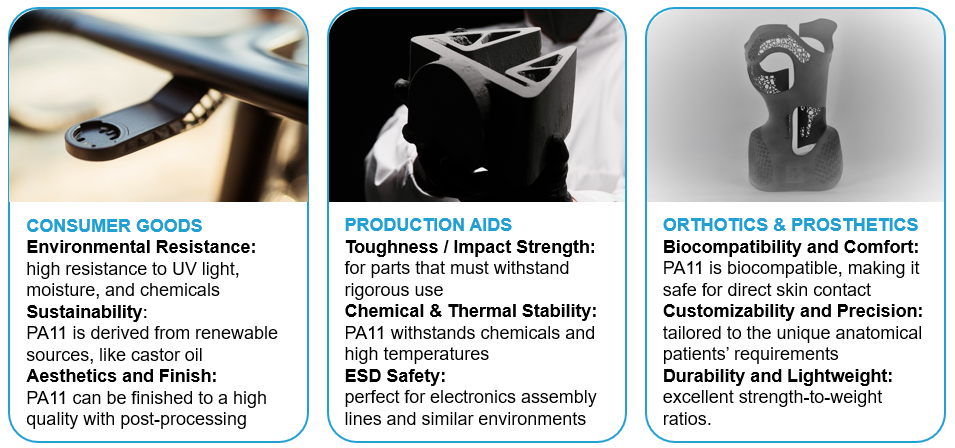

From automotive to medical applications, PA11 is the perfect choice to produce parts that need to withstand high mechanical stress and is a sustainable alternative to PA12 for functional prototyping, on-demand spare parts and individualized components requiring skin contact.

PA11 is 100% bio-based polymer made from castor oil and offers exceptionally high toughness. As a powder-based technology, the surface finish is uniform and smooth to the touch without visible layers. PA11 is available in unfinished form in both white (SLS technology) and gray and is a versatile polymer with excellent mechanical properties. PA11 printing technologies also offer a variety of finishing options from dying to chemical smoothing, giving the quality and aesthetics of injection molded plastics.

Our PA11 powders are compatible with several SLS systems in the market. Check out the updated printer compatibility list here.

Sustainable Optimization with Ultrasint® PA11

The utilization of 3D printing allows for the mass customization of products along with sustainable supply chain optimization with materials such as biobased Ultrasint® polymers. Forward AM provides 3D printing solutions along the entire Additive Manufacturing value chain. From consultancy and development, through bespoke design, digital simulation and prototype printing, to finishing and exhaustive component testing.

By implementing Additive Manufacturing technologies, customers and partners benefit from Ultrasint® PA11 through its excellent toughness. It also offers versatile applications from prototyping to special functionalities as well as high machine compatibility along with suitability for skin contact.

Our Ultrasint® PA11 products are bio-derived powders known for their high toughness, offering excellent ductility and impact strength across various applications. Our extensive portfolio includes PA11, PA11 ESD, PA11 CF, and PA11rCF – all advanced materials with advanced properties such as:

- 100% Bio-Based: Derived from sustainable castor beans

- Biocompatible: Suitable for skin contact

- Enhanced Durability: Superior elasticity and ductility compared to PA12

- High Impact Resistance: Exceptional toughness that rivals conventional plastics like ABS and PA6

- Health Safe: Meets USP Class VI requirements for medical and food contact

Ultrasint® PA11 ESD offers electrostatic discharging PA11 powder for highest process safety in application and is ideal for creating ESD-safe prototypes and small-scale parts, as well as custom tools and fixtures. It prevents electrostatic damage by discharging unwanted charges

Ultrasint® PA11 rCF is a top choice for strong, rigid, and lightweight parts. This recycled material maintains excellent ductility and impact performance, ensuring optimal mechanical strength and rigidity. This material also halves the carbon footprint compared to standard carbon fiber materials*.

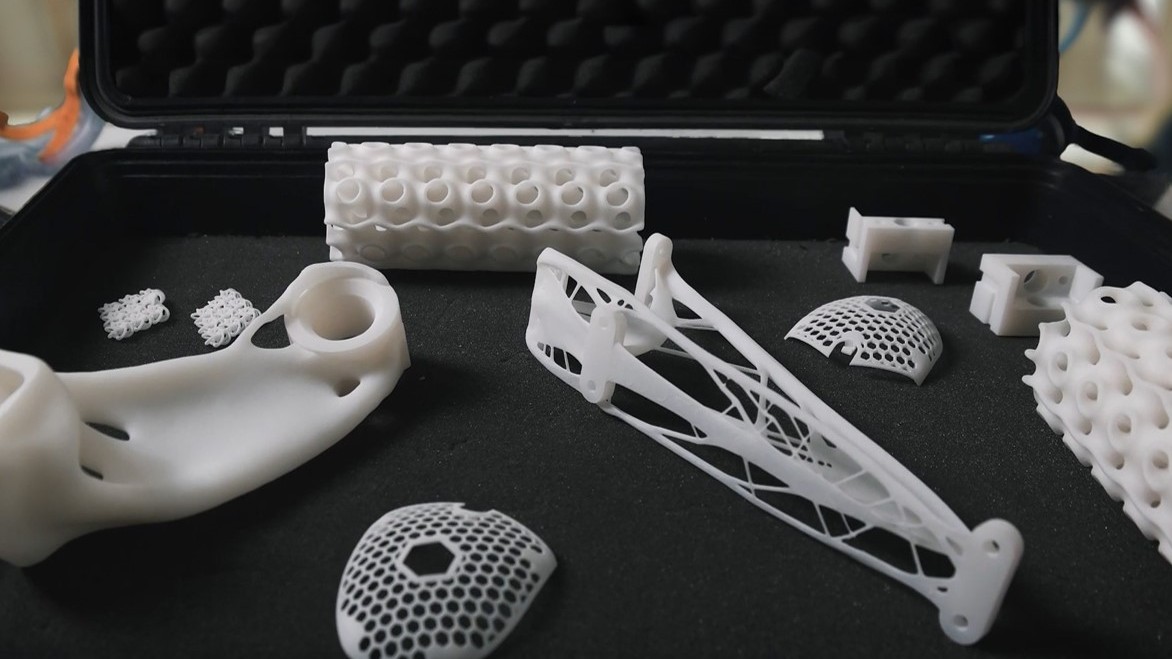

Example of 3D Printed Parts with Ultrasint® PA11 – Picture Courtesy of PARTS ON DEMAND (3D Printing Service in the Netherlands)

SLS Technologies and Recycled Materials from Arkema

SLS 3D printing is a method where a laser selectively fuses together powdered plastic to build objects layer by layer from a digital design. It is great for creating small to medium size geometries as well as prototypes or end use parts. Our Ultrasint® powders offer a versatile material portfolio for this method of printing with no support structure required and material recyclability through Arkema.

As a valuable partner to Forward AM, Arkema plays the role of intermediary by matching customers who want to recycle, with those who want to source recycled materials. They work to mechanically recycle the used powder and parts into raw material for new applications. This mechanical recycling allows another ~80% further reduction in CO2 impact.

Polyamides like Nylon PA11 are well-suited for additive manufacturing, especially SLS 3D printing. Known for their strength, resistance, and durability, these nylons are widely used in both traditional and 3D printing production.

PA11 is the perfect fit for multiple applications

Samples printed with PA11 CF and PA11 rCF.

Comparing Ultrasint® PA11 to a standard PA12

Impact Resistance – We conducted impact resistance tests comparing SLS printed Ultrasint® PA11 with PA12. The tests involved a vertically aligned tube from which a steel ball was dropped. The results indicated that while the PA12 sample broke, the Ultrasint® PA11 sample withstood the impact, remaining undamaged. The SLS printed Ultrasint® PA11 demonstrated enhanced impact durability, even at temperatures as low as -30°C.

Impact Resistance: Ultrasint® PA11 Vs. PA12 – Courtesy of ARKEMA

Ductility – We subjected both materials to multiple cycles of bending and unbending. The Ultrasint® PA11 samples retained their toughness and flexibility, showing no signs of breaking.

Ductility: – Ultrasint® PA11 – Courtesy of ARKEMA

Ductility: PA12 – Courtesy of ARKEMA

Canyon 3D printed computer mount (Source: Canyon)

Ultrasint® PA11 Use Case

Designing and manufacturing an optimized bike computer mount for exceptional performance.

- Material / Product: Ultrasint® PA11 Black CF, Ultrasim® 3D Services & Solutions

Striving for improved performance, Canyon, a market-leading bike manufacturer based in Koblenz, Germany, investigated ways how to optimize their computer mount. The requirements for the new mount were clear – being as light and as steady as possible to always ensure excellent readability of the bike computer during the ride.