Additive Manufacturing Keeps Olympia Dream Alive

Competing in the Olympic Games is a dream come true for every athlete. Every participant works tirelessly for the perfect day to score a personal best or even stand on the podium and feel the weight of a medal around their neck.

But after a bike accident, the Olympic dream was almost over for the French biathlete. Discover how Additive Manufacturing helped in keeping the Olympic dream alive.

To prepare for the Winter Olympics 2022 in China, the French national team of biathletes was in their training camp in Norway. One of them had a cycling accident in July 2021 and fractured his radius and ulna by trying to cushion the fall. After a surgery where the bones had to be secured with a metal stabilizer, the recovery period was a couple of months.

The athlete had difficulties with the supination of the forearm and was extremely limited regarding the deviation angle of his ulnar. Those limitations made it impossible to shoot a standard biathlon rifle in a prone shooting position.

The French National Team worked with the French company Athletics 3D to modify the rifle. The company is specialized in building customized sports gear with the help of Additive Manufacturing. The goal of the modification was to enable the athlete to shoot despite a limited ulnar deviation angle. Therefore, the hand stop was modified. The hand stop is a sling that is attached to the bottom of the rifle’s stock. With the freedom of design that 3D printing offers, it was suited ideally for this job and was maybe the only manufacturing process able to deliver the needed modification.

“The first thing we changed was the angle at which the hand stop was held to enable aiming without twisting the wrist. This way, we solved the problem of limited ulnar deviation angle. In the second step, we increased the area of contact between the hand stop and the palm to provide more stability in a position our client had not trained for”, explains Clement Jacquelin, CEO, and founder of Athletics 3D.

At the first shooting session after the accident, which took place in September 2021, the redesigned 3D printed hand stop achieved compelling results. Interestingly, the new hand stop made the shots more precise. However, it had the downside of slowing down the shooting rate.

Suitable Material and Printer are Essential

But when it comes to 3D printing, the used material is as essential as the printer and the design. Clement Jacquelin explained that it was crucial to choose the right material and a lot of thought went into that decision.

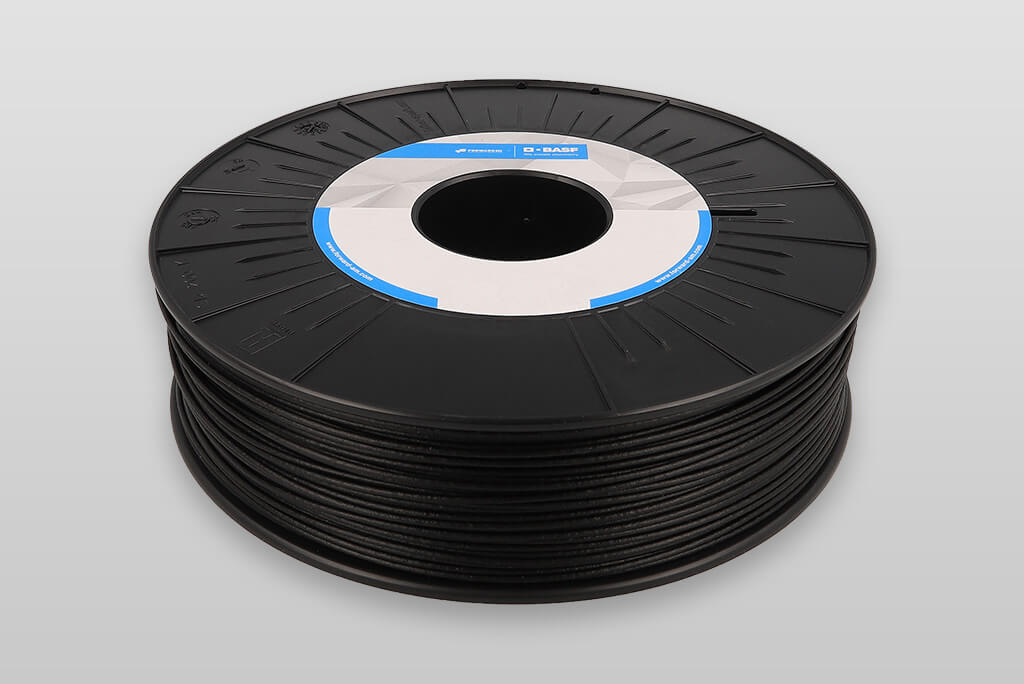

“We could not just use popular filaments like standard ABS or PLA. The part had to withstand significant stress, be resistant to impacts, and have a great surface quality. This alone limited our options to just a few candidate materials. Finally, what really sealed the deal for BASF Ultrafuse PP GF30 was its thermal stability”- Clement Jacquelin.

The Ultrafuse PP GF30 is part of the reinforcement line and is one of the most preferred thermoplastics. Besides thermal stability, it also has excellent chemical resistance, low density, as well as low moisture uptake, and improved UV resistance.

A big reason why Athletics 3D choose to use the Ultrafuse® PP GF30 was its ability to work normally in cold environments.

“Most polymers do not work well in such low temperatures. Materials like PLA or even ABS tend to become brittle when it’s freezing. That’s why French coaches insisted on choosing the material that could perform in low-temperature conditions. Thanks to BASF Ultrafuse PP GF30 we had no problem with that. The material’s exhibited the same, excellent performance in both freezing cold and relatively mild temperatures just below 0 °C” – Clement Jacquelin.

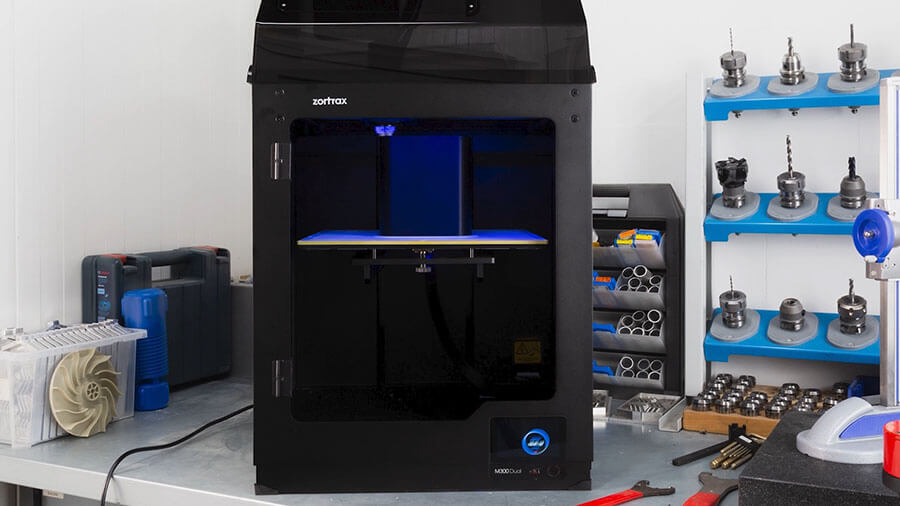

The Ultrafuse filament was then used to create the hand stop on the Zortrax M300 Dual printer.

“3D printers often have issues with accurately reproducing irregular, organic shapes. Performance in tasks like that lets you immediately tell the mediocre 3D printers from the really good ones. Ergonomic shapes we use in our sports gear are always challenging and the utmost precision is necessary to achieve the desired effect. That’s why we chose the Zortrax M300 Dual” – Clement Jacquelin

The Zortrax M300 Dual has the advantage of being able to print soluble support structures. These structures can be removed without damaging the surface of the printed part. Furthermore, the Zortrax software Z-SUITE provides predefined printing profiles for supported materials. This meant that the Zortrax engineers had already tested all settings for the Forward AM Ultrafuse PP GF30.

Ultimately, the national team decided against continuing the modified hand stop, as a higher shooting rate was prioritized. But it allowed the French athlete to start the training process two months earlier than expected and kept the Olympic dream alive.

If you want to learn more about this extraordinary story, check out the Zortrax blog post. It is not the first time that biathlon and Additive Manufacturing crossed past, find out more in our use case – Elite Biathletes Reach Peak Performance with Athletics 3D and Forward AM

Share this page

Other Blog Posts

Forward AM and the UltiMaker Factor 4 – Delivering Industrial-grade Performance

Forward AM offers a wide range of high-performance and certified materials that open a huge range of new 3D printing applications…

LAYERbyLAYER: A Conversation with Jörg Gerken of rpm rapid product manufacturing

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.

LAYERbyLAYER: A Conversation with Janet Dickinson of Endeavor 3D

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.