Only together can we create a better place

#ProjectZero

#ProjectZero - a new initiative at Forward AM

#ProjectZero is a long-term commitment to reducing our impact on the planet by developing sustainable products, solutions, and production methods, while also studying the impact of the 3D printing industry, and evolving the way we work through the education and encouragement of our team to make responsible choices.

Discover the key components of #ProjectZero

Developing sustainable products, solutions, and production methods

- The Carbon Compensation Program for PP – offering customers the opportunity to offset materials with the goal to include TPU in the near future

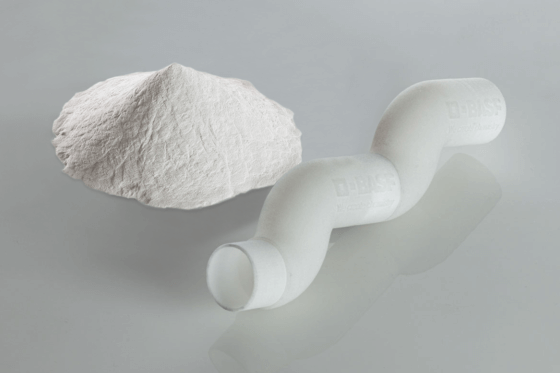

- The launch of Ultrasint® AP26 with a 100% recycle rate and highly recyclable Ultrasint® PP1400 Black, both innovative materials resulting in significantly reduced waste.

- Focused efforts on the production of recycled spools and optimized packaging

- Creation and implementation of a Net Zero booth at Formnext – constructed favoring sustainable materials, an open layout requiring less material, and optimally designed for reuse as an exhibit space in the future.

- Coming soon: Powder and parts recycling program at Sculpteo

Studying the impact of the 3D printing industry

- A steadfast commitment to completing Life Cycle Assessment (LCA) studies

- Offering partners the ability to reduce their carbon footprint by offsetting emissions

- Coming soon: SEE Balance Study

Evolving the way we work

- Implementing new business practices to reduce waste and save energy

- Creating an Ecological Committee to provide innovative ideas and project oversight

Educating and encouraging our team to make responsible choices

- Finding ways to encourage using public transport or cycling to work

- Expanding recycling efforts within our facilities to work towards becoming a zero-waste office

Learn more

3D printing and spare parts: Discussion on the environmental benefits

Sylvain Haasser (Head of Alternative Solutions at Groupe SEB), Pierre-Jacques Lyon (Co-founder & CEO of Marklix), and Nicolas Mathian (Head of Sustainability at BASF 3D Printing Solutions) agreed to discuss the production of spare parts and the role of additive manufacturing

How Ultrasint® TPU Enables a Recycling Stream

Discover how Ultrasint® TPU can be sustainable within the production process and beyond.

Discover how Sustainable our Filament Business Line really Is

We not only have sustainable Ultrafuse® materials but also support other initiatives to be more sustainable. Find out more!

For a more Sustainable Tomorrow – What Additive Manufacturing Brings to the Table

Circular economy, biodegradability, recyclability – these are just some of the terms being used when talking about sustainability. With climate change being the biggest challenge of our time, switching to more sustainable alternatives undoubtedly has to become integral to every aspect of society and business.

Building a Sustainable Future – Forward AM Initiatives

Additive Manufacturing holds tremendous potential to advance sustainability in comparison to traditional manufacturing – such as on-demand and on-site production, reduced waste and energy use as well as design-optimized parts resulting in lightweight components to just name a few.