SPEED-UP MANUFACTURING: 3D PRINTED RAPID TOOLING

Let us help accelerating your go-to-market

With 150 years of chemistry mastery, BASF can help you integrating tradition and innovation, providing rapid tooling solutions on the modern factory floor using additive manufacturing (3d printing) technology.

We know the benefits of conventional tooling, but also its challenges

Integrating rapid 3D printed tooling with traditional manufacturing processes for small-scale production or prototyping can help you address well-known challenges effectively:

Supply Chain Disruptions

Unpredictable issues can stop material flow, affecting production timelines and part availability.

Lengthy Lead Times

Traditional processes often involve slow, labor-intensive methods, delaying product development and market entry.

High Upfront Costs

Significant investments in molds and tools are required before production, impacting smaller runs and design changes.

How does 3D printing for rapid tooling solve these challenges?

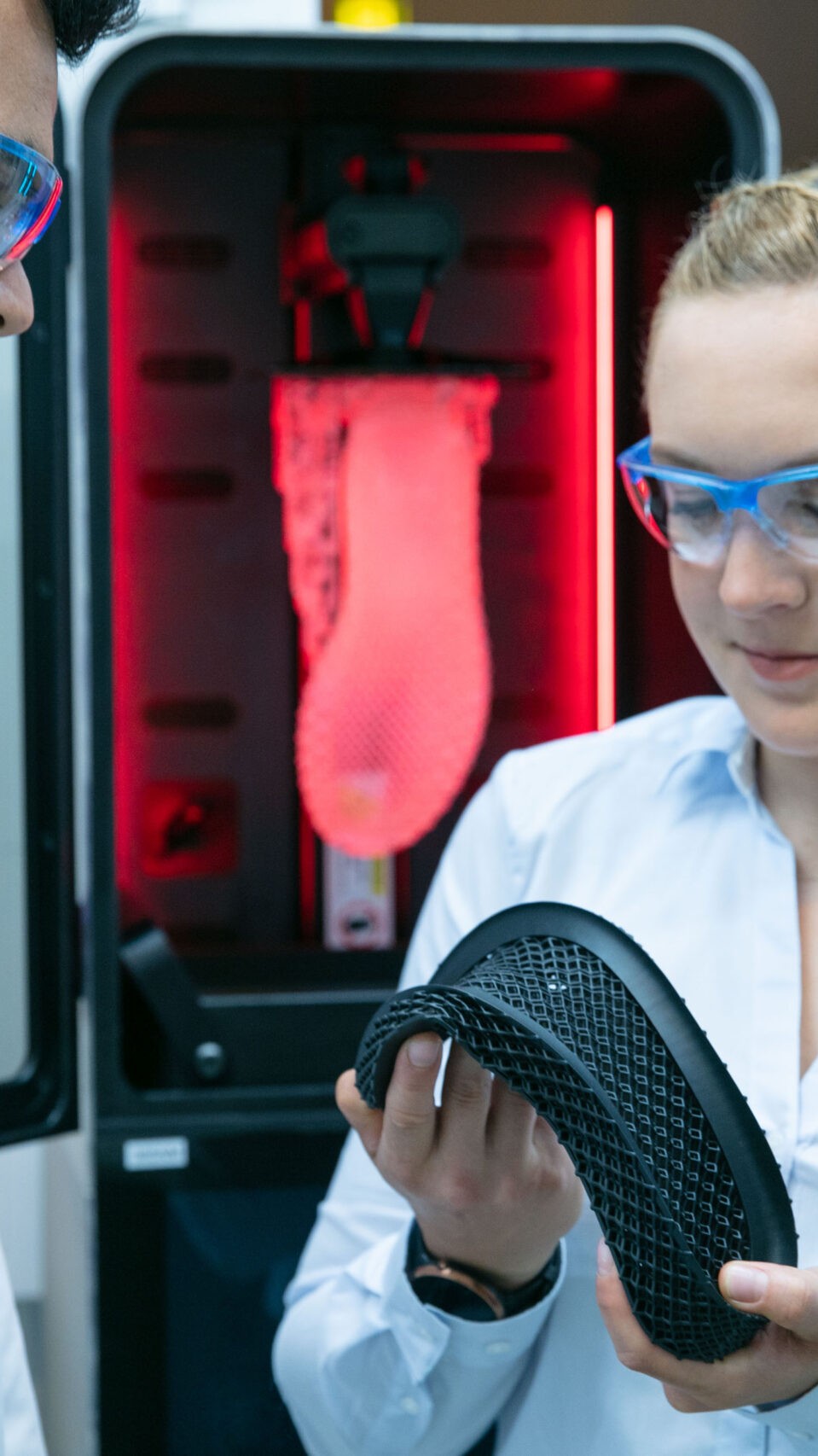

Incorporating 3D printed rapid tooling into your development process revolutionizes how you bring products to market. It not only accelerates product development and iteration but also significantly improves product quality. By using rapid tooling, you’re able to test designs and materials efficiently before scaling production, offering a cost-effective solution for producing bespoke or small batches of final products.

With the option to create molds on-demand, either in-house with your own 3d printer or via printing services, this process streamlines the entire production process. This results in shorter supply chains, reduced lead times, lower costs, and better protection of intellectual property, positioning your company for agile market responses, sustainability, and competitive advantage.

Discover BASF Forward AM, your Rapid Tooling Partner

Your additive manufacturing experts dedicated to accelerating your entry into rapid tooling.

As an additive manufacturing materials and solutions provider, we’ve developed tailored materials for the tooling process, ensuring optimal properties, machinability and durability. This commitment allows BASF Forward AM to redefine additive manufacturing, providing advanced solutions for accelerated, cost-effective, and resilient tool production.

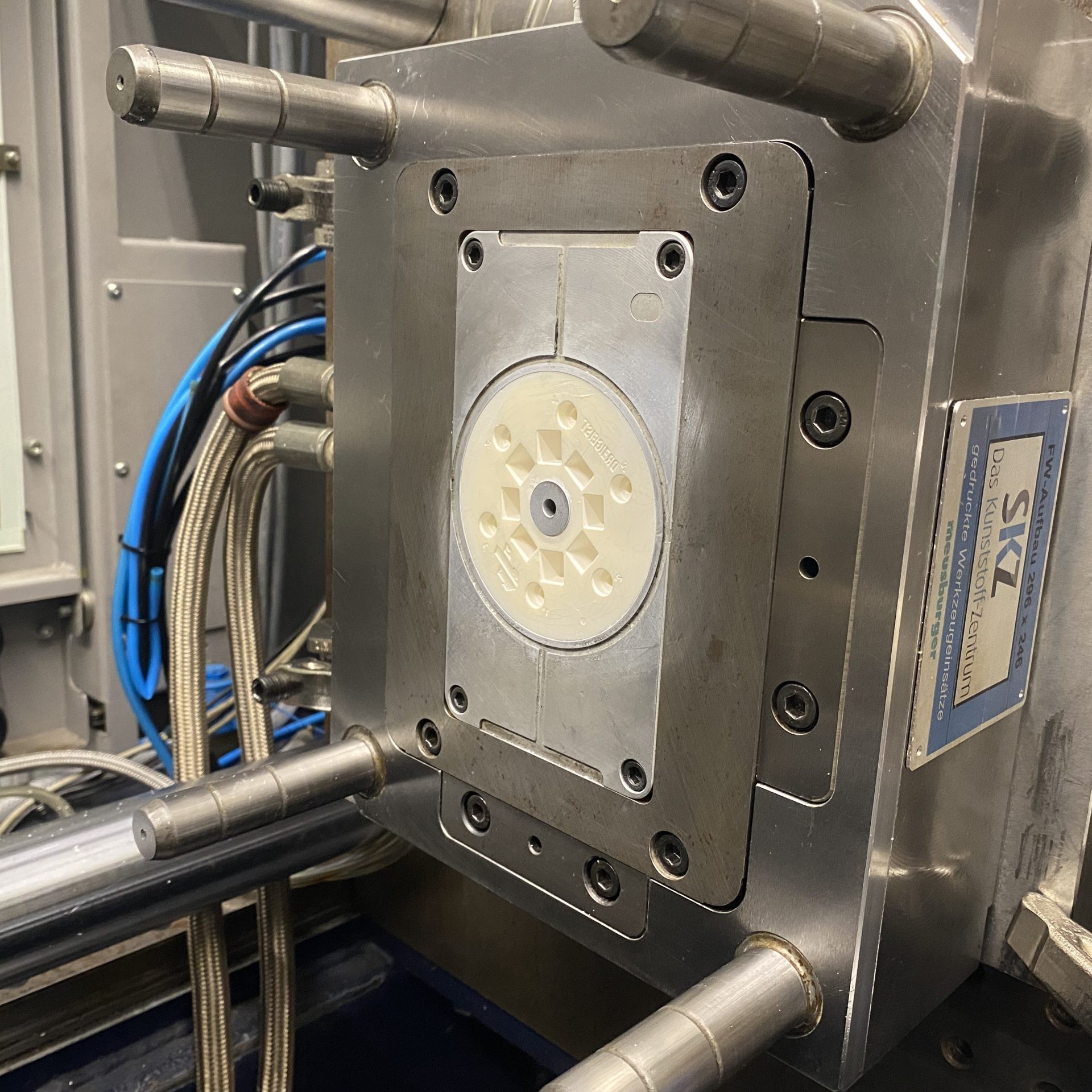

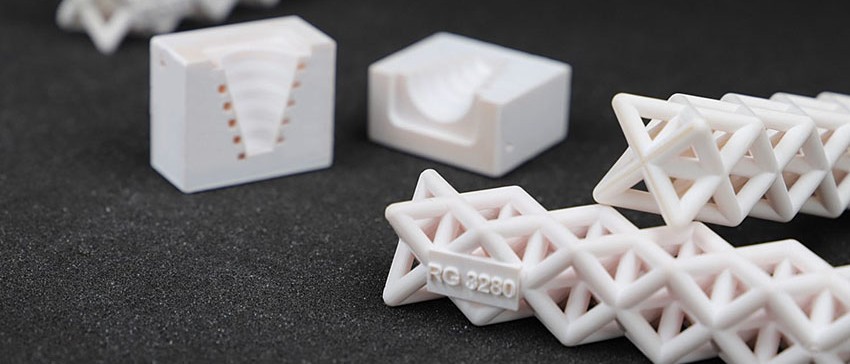

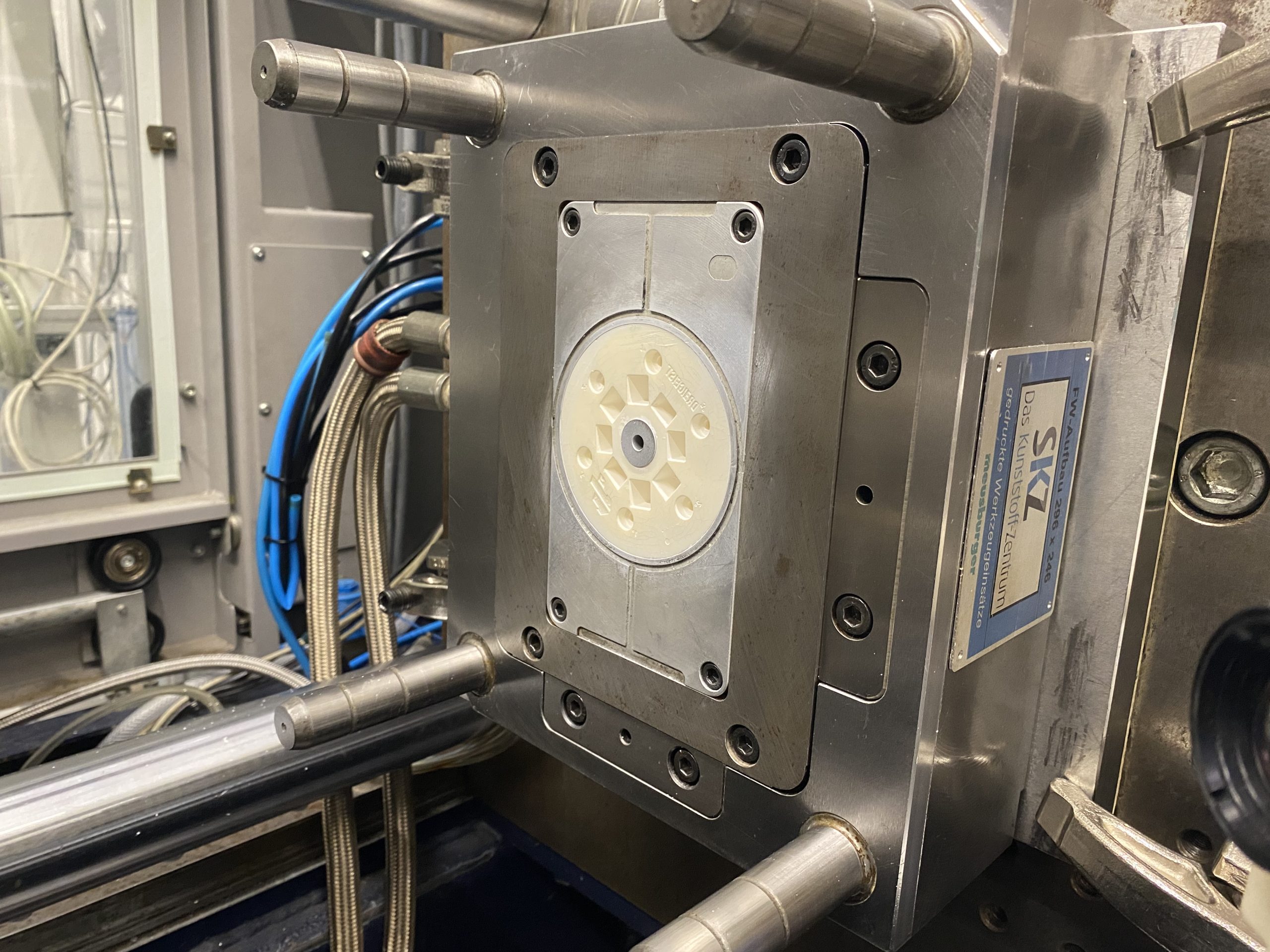

CASE STUDY: DREIGEIST & SKZ

Advancing Rapid Tooling with 3D Printed Injection Molding Inserts

Rapid Tooling merges 3D printing with traditional toolmaking to revolutionize product development. It speeds up prototyping, enhances component design, and supports efficient low-volume production. This case study focuses on leveraging BASF Ultracur3D® RG 3280 ceramic filled to create 3D printed injection molding inserts.

“Rapid tooling using BASF Forward AM's materials saved us significantly, cutting costs from €2,500-€6,000 to under €500 per tool. Traditional milling took 4-6 weeks for delivery; in-house 3D printing got us results in just 9 hours. A game-changer for our production process!”

— Christopher König, Co-Founder and CTO of DREIGEIST

Let's talk about 3D Printing!

Fill out the form, and we’ll connect to understand your project needs. We provide tools, best practices, and support to unleash rapid tooling’s full potential in your factory — from setup to realization, empowering your manufacturing success.