Welcome to the New Era of Industrial Additive Manufacturing

Transform your vision into reality

Discover the worlds largest selection of industrial 3D printing materials; filament, powder, photopolymers and pellets. Explore infinite possibility with our full service additive manufacturing.

Achieve more with Forward AM

BASF Forward AM collaborates with designers, engineers and industries to shape the future of additive manufacturing.

We provide 3D printing solutions for the entire value chain. From consultancy and development, bespoke design, digital simulation and prototype printing to finishing and testing. We invest in international research and development whilst delivering value through high-quality materials, applications and processes.

Forward AM TPU: A Thermoplastic Polyurethane Supercharged by 3D Printing Technology

TPU is used to make products with tensile strength, durability, and resistance, and unlike many other materials, it can be recycled to minimise waste. Combining this amazing material with 3D printing technologies, allows you to manufacture virtually any shape, with any kind of flexibility, on-demand.

Forward Thinking Design

Create components that outperform their competitors. Innovate new ideas.

Solve complex challenges. Accelerate your time to market.

3D printing technology can generate virtually any three-dimensional shape you can imagine.

Design

Revolutionise and enhance the capabilities of the additive manufacturing processes, the freedom to create innovative designs you thought impossible.

Versatility

High tensile strength, flexibility, and shock absorption, suitable for diverse applications, with varying levels of hardness and rigidity. High quality finish with resistance to abrasion, impact, chemicals, and UV light.

Customisation

Exceptional flexibility, moisture impermeability, and resistance to dirt and oil. The perfect, smoothed finish in various colours.

Sustainability

Fully recyclable TPU reduces waste and promotes sustainability. With industry leading refresh rates whilst maintaining the highest printing quality.

Dream. Design. Make.

VIEW OUR PRODUCTS

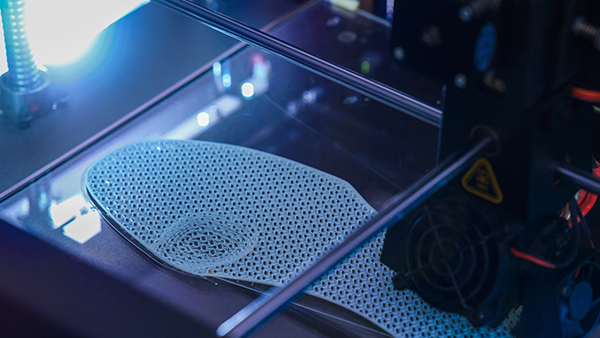

Powder Bed Fusion (PBF)

Ultrasint® TPU is a versatile thermoplastic polyurethane (TPU) powder ideal for various applications, offering shock absorption, energy return, and flexibility. It’s perfect for sports protection gear, footwear, orthopedic models, car interiors, and industrial tools. Our range includes TPU01 for HP MJF 3D Printers and tailored solutions like TPU 88A and TPU 90A LT for SLS 3D Printers. Whether you need durability or versatility, Ultrasint® TPU ensures quality and functionality for your projects.

Fused Filament Fabrication (FFF)

Ultrafuse® Flexible Filaments are designed for industrial use, offering soft haptics, superior strength, and remarkable flexibility. With outstanding rebound and abrasion resistance, they ensure enduring flexibility for long-term applications. Choose from our range of four TPU filament types tailored to provide the perfect shore and specifications for your specific application needs. Elevate your projects with unparalleled quality and reliability.

Additive Manufacturing: Solving Real-World Challenges

Collaborating For Innovation

At Forward AM we operate and collaborate seamlessly throughout the entire value chain, offering comprehensive end-to-end solutions by integrating high-quality, pioneering materials with cutting-edge engineering services. The key to progress lies in unity, recognising that no one can succeed in isolation. Additive Manufacturing, in itself, is merely a technology; however, its true value emerges when partners collectively align and collaborate across applications, materials, and processes to form a dependable and scalable solution.

Original Equipment Manufacturers

A partner for evolution. We work with OEMs to find new and fascinating ways to leverage 3D printing technology and enable them to use it at an industrial scale. Supporting the creation of elegant solutions for everyday problems, we believe that every 3D-printed product should be functional and pleasing to the senses: robust, reliable and refined.

We actively support the design and production of products that minimise waste and energy consumption, contributing to a more sustainable future, we’re ISO 14001-certified for our commitment to environmental management.

Service Bureau

A partner for excellence. We work with service bureaus to enable them to continue their track record of high-quality standards, fast printing speed and outstanding customer support. Supplying a diverse and superior range of materials that meet specific industry standards. We ensure reliability, consistency, and compatibility across various 3D printing technologies.

Continual collaboration and constant innovation addresses evolving market needs for material development. Timely access to these cutting-edge materials, along with outstanding technical support, means we help service bureaus to maintain operational efficiency and meet client demands.

Machine Manufacturers

A partner for progress. At Forward AM we offer access to a varied material portfolio, including advanced options, enabling manufacturers to stay competitive and pioneer the next generation of 3D printers. Collaborative partnerships for ongoing research and development contribute to addressing specific application needs, ensuring a seamless integration of materials into new machine design and development.

Providing market-leading, reliable materials compatible with diverse and innovative printing technologies, alongside consistency in material properties, is vital for our partners to achieve success.

Ultrasim® 3D Service Portfolio

Service solutions that drive the industrialisation of additive manufacturing. 3D printing is more than just a technology; it’s a gateway to creativity and innovation. Each project becomes a platform to delve into new design horizons, and our commitment extends beyond the material itself. Our comprehensive services are designed to support our customers throughout the entire additive manufacturing process. From aiding in the initial design and simulating part behaviour, to meticulously handling the post-processing of the final application. Our approach ensures tailored solutions that align seamlessly with your objectives.

Engineering Services

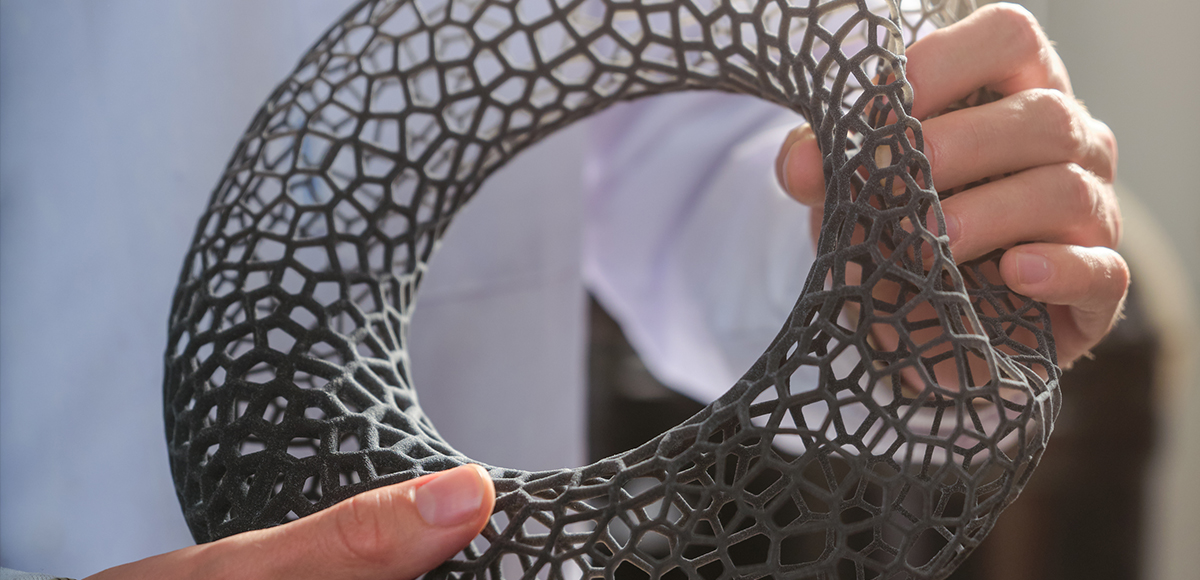

Elevate your capabilities with our unique software Ultrasim® 3D Lattice Design. Ultrasim® 3D Simulation, Cost Analysis and Life Cycle Assessment programs enable precise evaluation of product performance, sustainability and cost through advanced digital simulations. Combined with our material expertise, this software accelerates the 3D printing development process, whilst our depowdering and chemical smoothing services enhance performance and elevate the aesthetics of your products and components, empowering you to achieve optimal results efficiently and effectively.

Digital Solutions

Experience the efficiency of BASF Forward AM’s Ultrasim® 3D Lattice Library, designed to optimise designs for additive manufacturing by simulating part behaviour and selecting the ideal lattice for your application.

Powered by Hyperganic, the Ultrasim® 3D Lattice Engine tool offers one-click lattice engineering, providing pre-selected, validated lattice options specifically tailored for Ultrasint® TPU01. Simplify your workflow and increase success rates without high investment costs.

Forward AM TPU Video

Download our FREE Whitepaper

Harnessing Lattice Structures with Forward AM's Ultrasim® Service

Discover the power of lattice-designed applications in Additive Manufacturing (AM). This whitepaper explores how Forward AM’s Ultrasim® service empowers designers to optimize properties locally, revolutionizing industries with flexible materials.

Realising New Product Potential

Shifting the dynamics of design

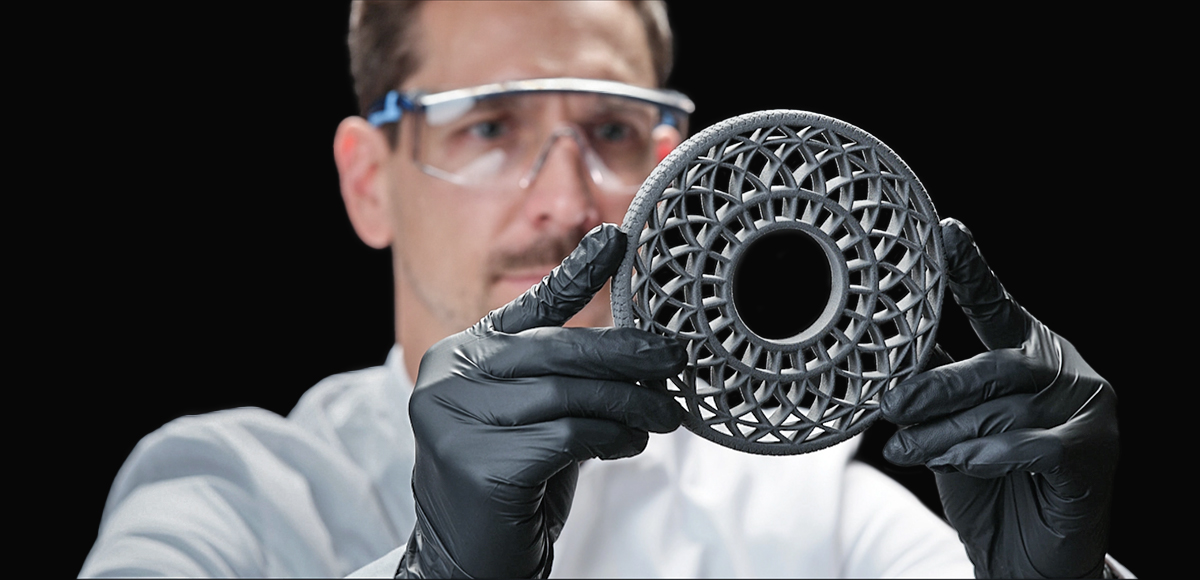

3D printed lattices are unlocking innovation and extending the capability of additive manufacturing. Now you can achieve what used to be impossible. Just one material, TPU, delivers impressive mechanical properties – including rebound, reduced weight and aeration – using this 3D micro-architecture.

Versatility Meets Strength

TPU has high tensile strength, with foam-like behaviour and great shock-absorbing capabilities, making it ideal for a wide range of applications, including sports, automotive, and orthopaedic modelling.

- TPU hardness and rigidity depends on the polymer blend

- Easily smoothed and coated for a high-quality finish

- Resistant to abrasion, impact, chemicals (such as oil and grease) and UV light

- Excellent interlayer adhesion, with no curling during printing

The Ultimate Finish in any Colour

Waterborne polyurethane coating with exceptional flexibility, moisture impermeability, and resistance to dirt and oil.

- Excellent adhesion - ideal for elastic 3D printing materials

- Available in standard and custom colours and finishes

- Low VOC content

Sustainable AM Evolution

Additive Manufacturing holds tremendous potential to advance sustainability in comparison to traditional manufacturing – with on-demand and on-site production, reduced waste and energy use as well as design-optimised parts resulting in lightweight components to just name a few. Minimising plastic waste and supporting sustainability by gathering both powder and end parts for recycling a minimum refresh rate ratio of 80% fresh/virgin powder to 20% pre-used powder, ensures optimal printing quality with maximum sustainability.

Download Data SheetImproving Rider Comfort

A new generation of motorbike saddle

How can you improve the in-saddle experience for motorcyclists while taking into account the biomechanical specifications of different customer groups, including sports, tourers, and off-roaders?

Here’s how we did it, in collaboration with OESCHLER.

See the full story

See the full story

A Big Step Forward in Prosthetics

Improving the fit of limb sockets

Until recently, the fitting of prosthetic limbs still relied on hand-crafting for creating the socket.

ProsFit was looking for an inner-socket material that offered a much higher level of comfort and quality of life for the wearer, and that would accelerate the design and production process for faster delivery.

Here’s what Forward AM helped them to achieve.

Achieving Safer Human-Robot Collaboration

Avoiding injury without harming productivity

In the manufacturing industry, ‘cobots’ are designed to work alongside humans in shared areas where, naturally, safety is a crucial consideration.

Here’s how we worked with OESCHLER to create a solution that enables humans and cobots to share a workspace without any safety risks – while still keeping productivity high.

Reinventing Head Protection: Tailored, Durable, Safe

Pioneering Custom-fit Helmets for Enhanced Athlete Safety

Athletes in contact sports often accept the risk of head injuries, but Xenith, collaborating with BASF Forward AM, developed a helmet that surpasses safety standards, providing custom fit and enhanced protection. Their innovative use of Ultrasim® and Ultrasint® TPU01 for 3D printing has led to helmets optimised for shock absorption, improving safety, comfort, and durability. Xenith's efforts were recognized in the 2021 NFL Helmet Challenge, highlighting their contribution to safer sports.

Are you interested in finding out how our products and services can drive your business forward?

We’re looking forward to hearing from you! Contact us now and we’ll get in touch.