Meet Our Tough Star: Ultrasint® PA11!

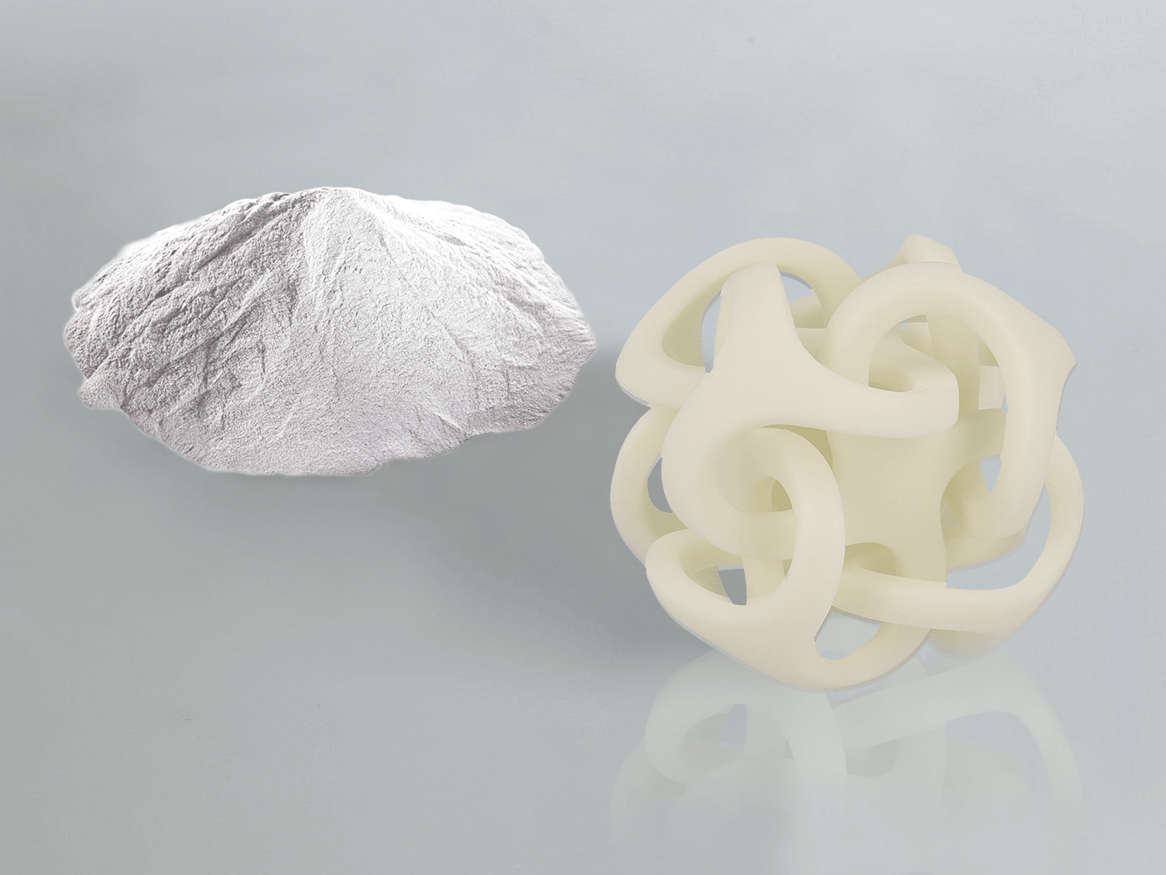

A wealth of applications, ease of use on any PBF equipment, convincing mechanical properties, and based on natural feedstock. One material has it all: Ultrasint® PA11. Let’s take a closer look at our compelling alternative to PA12.

Successfully certified for skin contact and cytotoxicity-approved, our SLS powder PA11 is the go-to-material for all applications requiring safe skin contact. This enables a broad spectrum of applications, for instance in the orthopedics industry and for all kinds of eyewear frames.

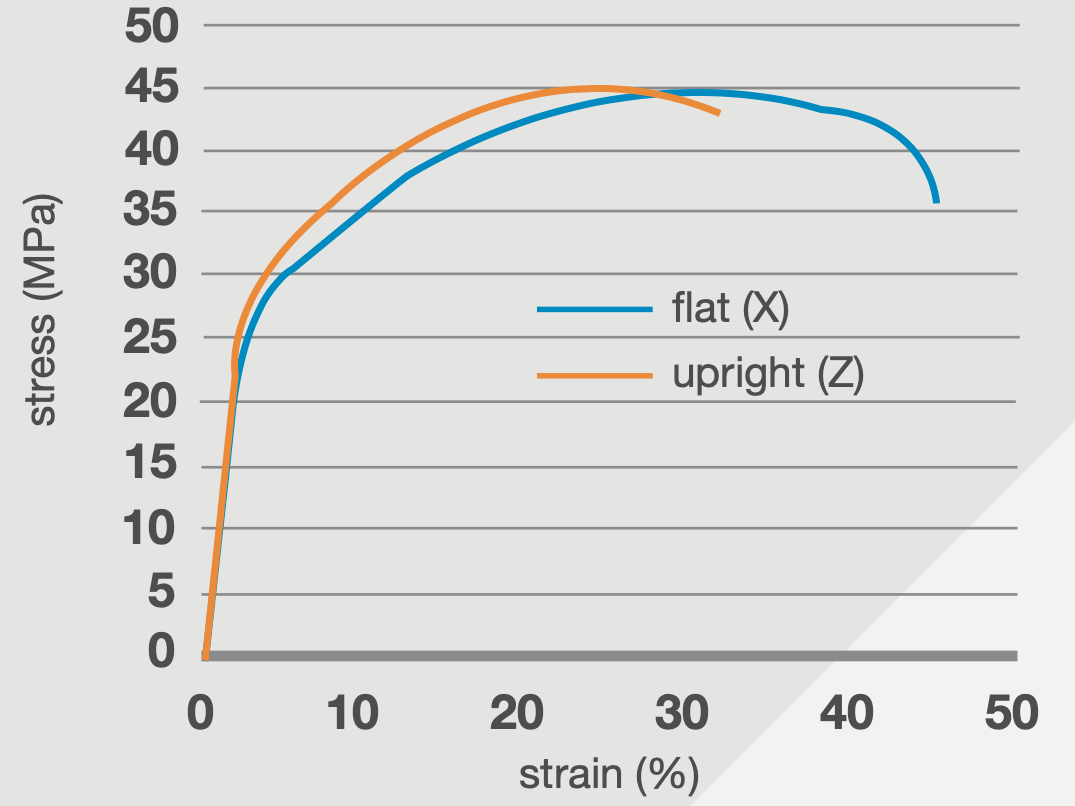

Looking closer at the mechanical properties of PA11, it offers a higher elongation at break and higher tensile strength than PA12, making it one of the toughest materials in the industry. With its exceptionally high ductility and impact strength it is ideally suited to any application requiring deformation and toughness, such as interior automobile parts or external fender structures. It is the perfect choice for functional prototyping, on-demand spare parts and individualized components for the automotive as well as the dental and medical industry thanks to its skin contact certification.

To top it off, PA11 is bio-sourced. Extracted from castor oil, it is derived from natural feedstock. All these benefits come with easy handling – Ultrasint® PA11 can be processed on any PBF printer equipment. Just decide for one of the two color options, black or white, and get printing!

What’s more, our extensive PA11 portfolio is being widened by further material versions, enabling a comprehensive range of applications.

Some applications just have to withstand a whole lot of punishment. Heat deflection and superior rigidity make PA11 GB30 the material of choice whenever reliable performance in challenging environments is required: Thanks to its reinforcement with glass beads, PA11 GB30 assures thermal stability and precise feature control of printed parts, ideal for thermally loaded components, e.g. in automotive engine compartments. In short, PA11 GB30 combines all the advantages of the Ultrasint® range with glass bead additives, making it an ideal powder for prototyping and limited-series production.

When considering applications in the electronics industry, PA11 ESD is the stand-out choice. Components printed with this material discharge unwanted electrostatic charges from sensitive components and systems, thereby reducing the risk of electrostatically induced noise, damage or even system failure. This powder is the right choice for ESD-compatible jigs, fixtures, housings and manufacturing aids for the electronics industry.

PA11 Black CF is our flagship material in this range, featuring carbon-fiber reinforcement that delivers class-leading mechanical performance of printed components when high strength and rigidity are crucial. Ultrasint® PA11 Black CF is the perfect choice for lightweight designs, such as individualized and low-run motorsport parts series.

Rounding it off, our Virtual Engineering Service is now available for Ultrasint® PA11 – making the whole wealth of simulation options accessible to you. Our Virtual Engineering Team uses Ultrasim® for mechanical modelling, digitally optimizing the weight and performance envelope of your printed parts. By identifying and eliminating structural weaknesses ahead of production and predicting the mechanical behavior of your parts, design iterations are greatly reduced, thus saving a great deal of time and money.

Are you interested in holding a part printed with PA11 in your own two hands? Thanks to the Sculpteo printing platform you can upload your file quickly and easily and get your parts printed with our PA11, PA11 ESD and PA11 Black CF here.

Share this page

Other Blog Posts

Exploring the Future of Injection Molding: A Dual Perspective

In the evolving world of manufacturing, the integration of traditional practices with innovative technologies is not just a trend…

Full Guide: Polyurethane Molds with Ultracur3D® RG 1100 B / xPRO1100-Black

In the rapidly evolving world of product development, speed and flexibility are a must. This is where 3D printed PU molds steps…

LAYERbyLAYER: A Conversation with Vanna Menco of Prosilas

Welcome to LAYERbyLAYER: Interviews with 3D Printing Services, a unique series brought to you by BASF Forward AM.