PP Line

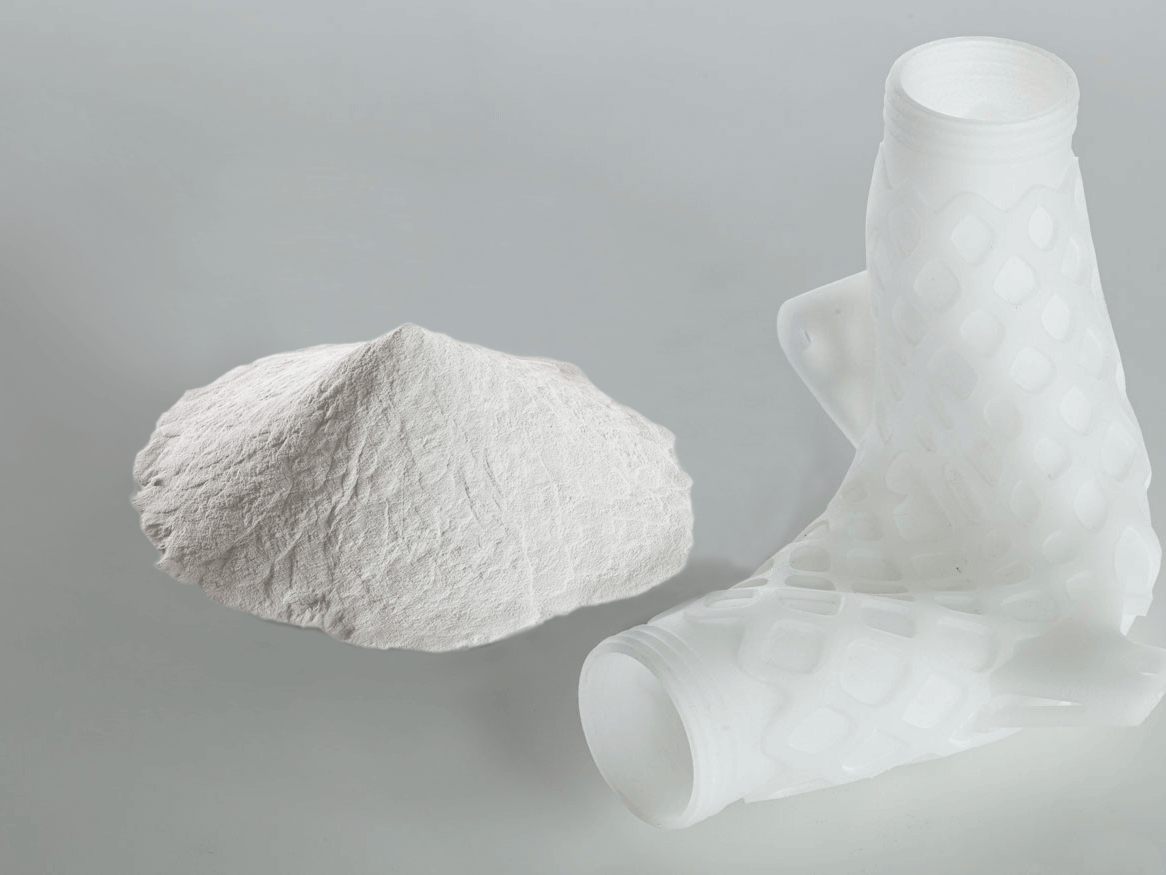

Advanced Polypropylene Powder for a Wide Range of Innovative Applications

Ultrasint® PP harnesses the properties of polyolefins for Powder Bed Fusion (PBF) technologies, making the rapid printing of individualized and functional serial production parts a reality. Thanks to the well-known characteristics of polypropylene, this powder delivers excellent chemical resistance, ductility and media tightness. Our enhanced formula goes one step beyond: In contrast to commonly used polyamides, Ultrasint® PP boasts excellent plasticity, higher elongation, durability, and low moisture absorption. The high rigidity of Ultrasint® PP makes the material especially well-suited for technical applications and durable 3D printed polypropylene parts, from prototyping through to functional parts. On top of that, it’s an economically attractive alternative to commonly used PA12, making it an interesting choice to expand 3D printing applications and volumes.

Ultrasint® PP Product Portfolio

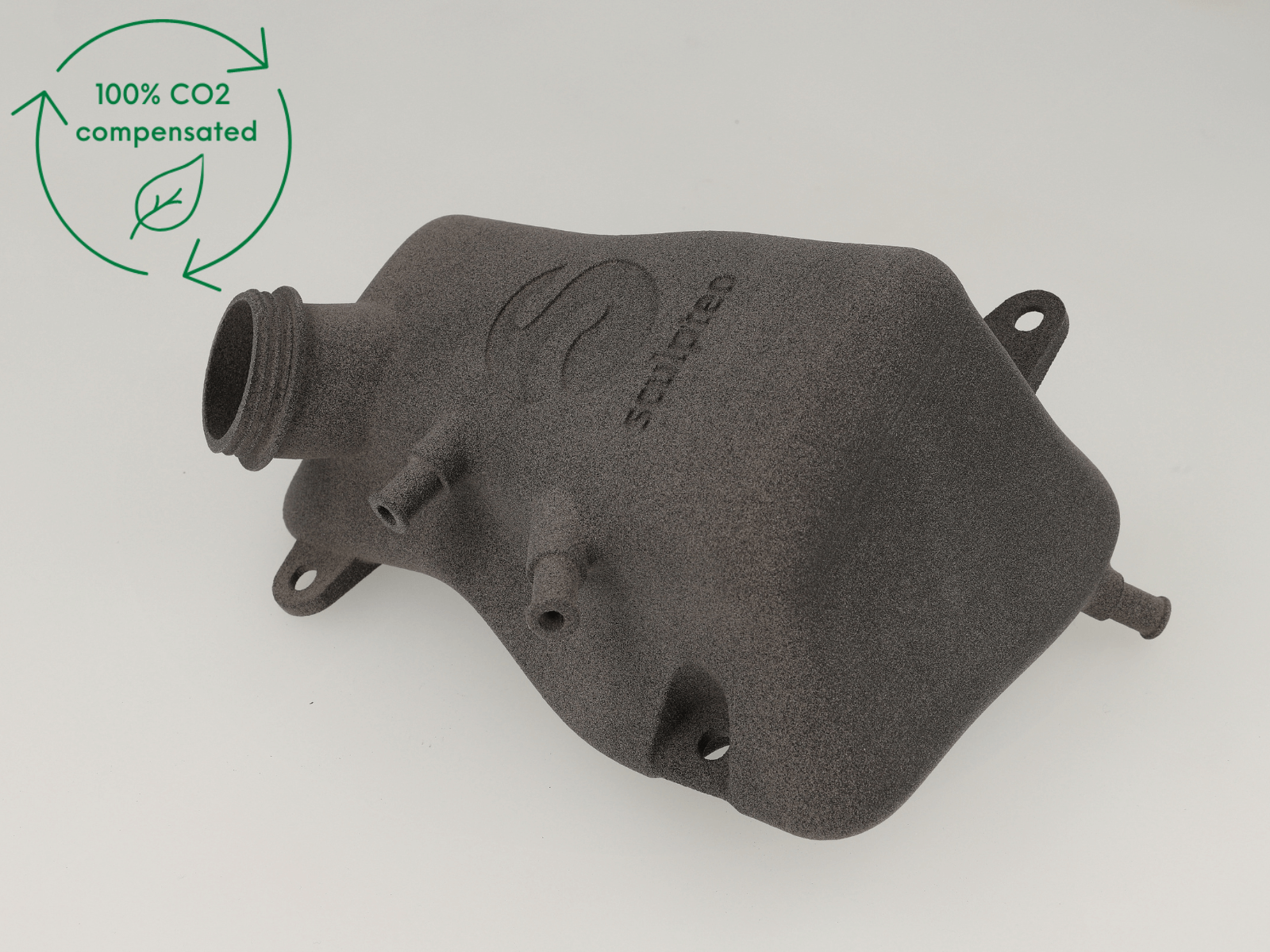

Ultrasint® PP 1400 Black

Advanced Polypropylene Powder for a Wide Range of Innovative Applications

Benefits at a Glance

- Easy to process PP

- Isotropic behavior

- Excellent chemical resistance

HP 3D High Reusability PP enabled by BASF

Fully functional polypropylene for use on HP JF5200 series printers

Benefits at a Glance

- Genuine PP material

- Functional performance

- Appealing cost per part

Next Steps

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!