Surfboard

Turning Waste into Surfboards

Project Breakdown

Industry

Consumer goods

Project

Surfboard

Customer

YUYO

Forward AM materials used

Ultrafuse® rPET

The ocean is their playground

And a playground everybody wants to preserve for future generations. No wonder surfers are highly concerned about ocean ecosystems and want to actively contribute to their protection. But their sport is itself a major obstacle, as the vast majority of surfboards out there are pollutive, non-recyclable, and toxic to ocean life (more information here). It’s clear that the surfer community is facing a critical paradox.

French company YUYO joined forces with Forward AM to overcome this contradiction – by developing a sustainable surfboard alternative.

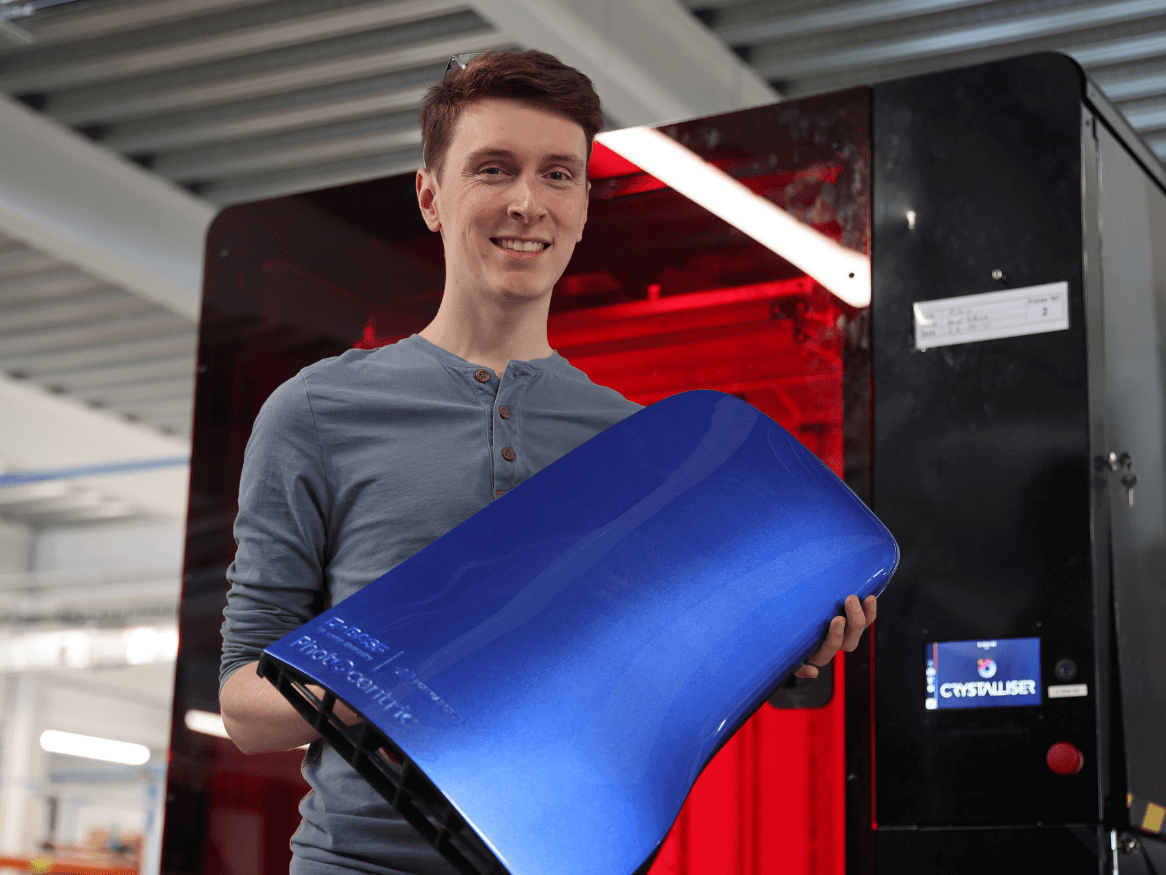

Using industrial-scale 3D printing technology and the latest biocomposite materials, YUYO and Forward AM designed a surfboard made completely of recycled materials. Even better, the design freedom provided by Additive Manufacturing now enables YUYO to customize their products to the max and give surfers the bespoke, sustainable boards they’ve been asking for.

Medical waste, surfboards and Additive Manufacturing – how do they all tie in?

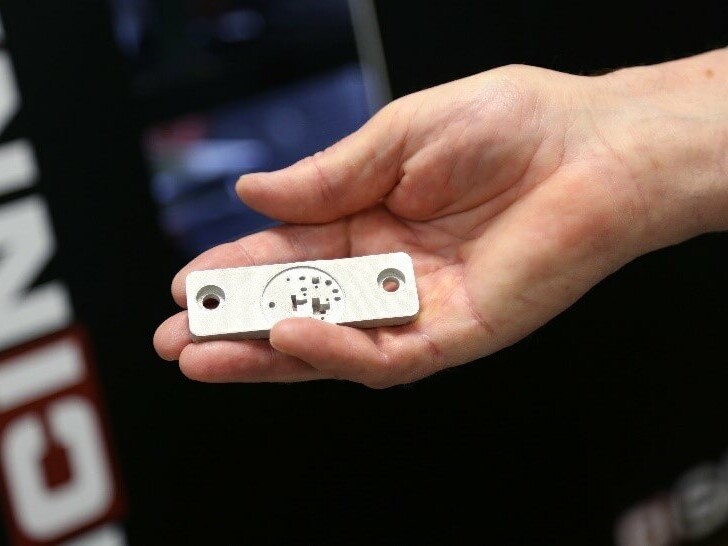

In 2018, YUYO founder Romain Paul heard about the high volumes of hospital waste, mainly as plastic packaging completely harmless to human health. Aware of this environmental issue, he researched the steps required to collect, sort, and process this medical waste – and the idea of using it as feedstock was born. The key to putting his brilliant concept into action was to find a material that consisted entirely of recycled medical waste and was ready for processing on large-scale 3D printers. Following extensive investigation, YUYO discovered there was only one recycled filament that ticked all the boxes: Ultrafuse® rPET by Forward AM.

The internal structure of YUYO’s surfboards is 3D printed with Ultrafuse® rPET that’s 100% recycled from waste medical trays used for sterilizing surgical tools. This filament is outstandingly reliable, always delivering the exact same characteristics such as identical viscosity and filament diameter. Quite simply, it prints as reliably as a regular top-grade virgin PET filament.

“Thanks to Ultrafuse® rPET we now have a filament that delivers the printing experience that we demand – every single time.”

Romain Paul, Founder of YUYO

Surf’s up, so we’ll keep it short. Ultrafuse® rPET is the ideal sustainable alternative to PET that also ensures outstanding 3D printing performance and easy handling. To top it off, the rPET core of the surfboard is covered with a layer of biocomposite: The result? A truly eco-friendly surfboard – the YUYO Natural Surfboard.

The result: Catch a wave with full peace of mind

To bring it all together: Right alongside the environmental benefits, Additive Manufacturing gives YUYO outstanding new design possibilities for their surfboards. Thanks to 3D printing, customization has never been easier.

“We can now produce custom, on-demand surfboards that match the performance of conventional boards in every way – and are harmless to marine ecosystems.”

Romain Paul, Founder of YUYO

Harnessing the huge potential of Additive Manufacturing now enables YUYO to produce on-demand bespoke surfboards responsibly. Thanks to Ultrafuse® rPET, YUYO is reducing medical waste, minimizing the environmental impact of surfboards, and helping preserve ocean ecosystems for the next generation of surfers.

Have we sparked your interest? Find out more about this project here.

Share this page

Next Steps

Reference Links and Documents

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!